INITIAL STATE

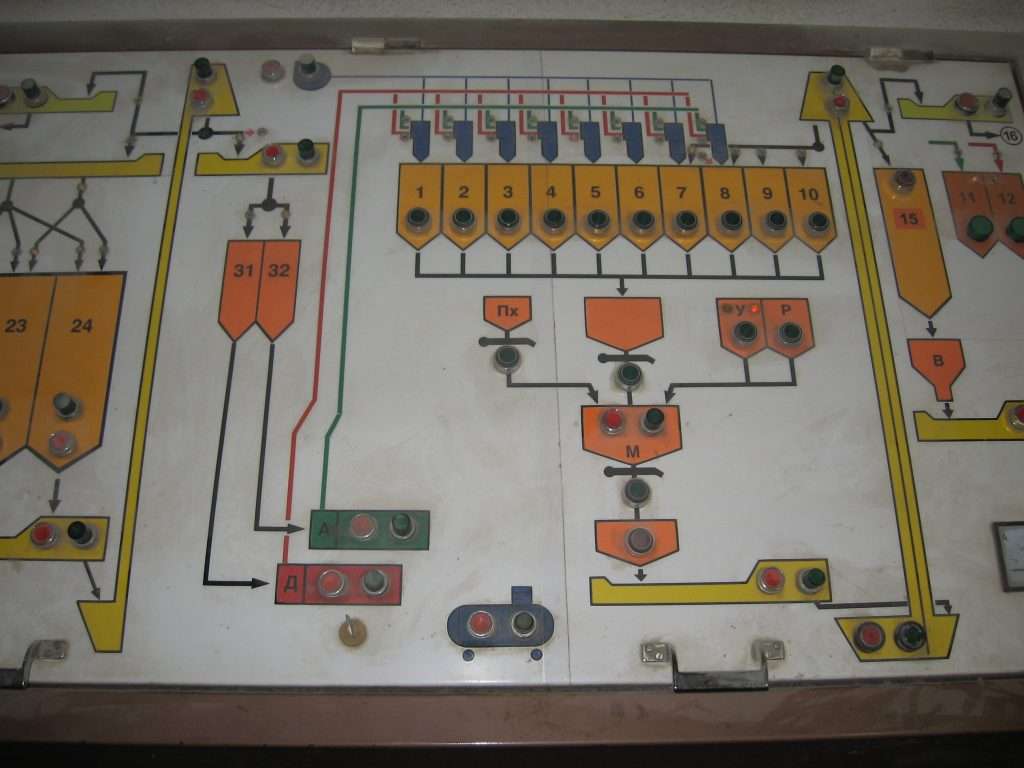

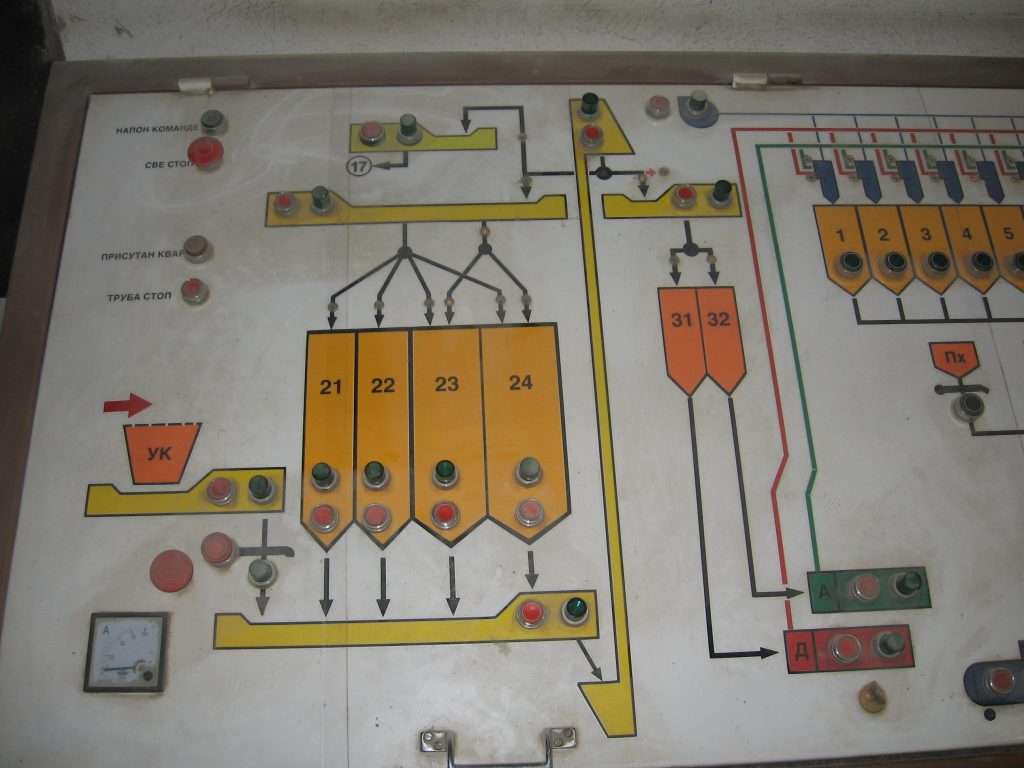

The animal feed factory SUNCE is one of the 3 largest producers of animal feed in this part of Serbia. The previous food synthesis process in the mixer relied on a very precise but rather slow weighing of the individual components that make up the final product using a mechanical scale with a moving weight. The entire process is further slowed down by the need for the worker to manually initiate the ignition of the screw conveyor motor of the appropriate raw material while the shutdown

the engine performed automatically. The entire process required the engagement of two to five workers during the entire process.

The idea behind the automatic control of the mixer's operation arose as a need to respond to increasing and serious market demands, the implementation of HACCP and ISO9001 standards, which by their very nature obligate the manufacturer to document and specify each phase in production, measures taken in the field of quality of goods and services which the manufacturer offers with an increase in the volume and dynamics of production.

By looking at the current situation, which can basically be described as manual process control, we came up with the idea to leave the management of the existing control panel to a powerful industrial PC with the implementation of a complete control and management information system necessary for further data distribution.

CONTROL SYSTEM

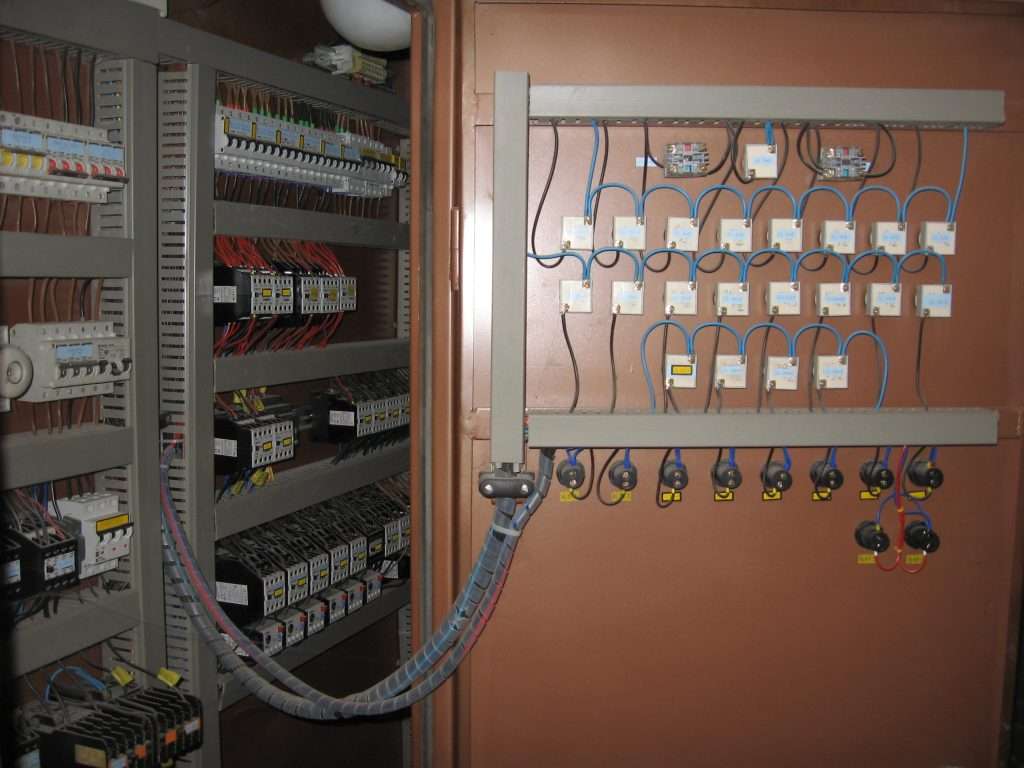

The integrated feed mixing management system is based on an industrial PC type A2

produced by Electronic Design. The A2 is equipped with a 32-channel digital input card and a 32-channel

digital output card with additional expansion slots. The taking of 12th material is controlled

silage, intake of water, oil and premix components. The entire controller is housed in a hermetically sealed cabinet

dimensions 750x1500x350 mm. All process parameters are set via touch panel display and numeric

keyboards. Management parameters and production results are organized in a database and can be accessed through them

Ethernet networks can also be accessed from remote locations. A specially designed application provides data on

production can be viewed, analyzed and printed in the form of a report.

The complete software is divided into three separate functional units - program modules:

PROGRAM MODULES

Recipe synthesis module

It combines the following functionalities

- Records of recipes in the database

– Component consumption statistics

– Expertise in the selection of raw materials

– Parametric management

- Optimization and synthesis of recipes

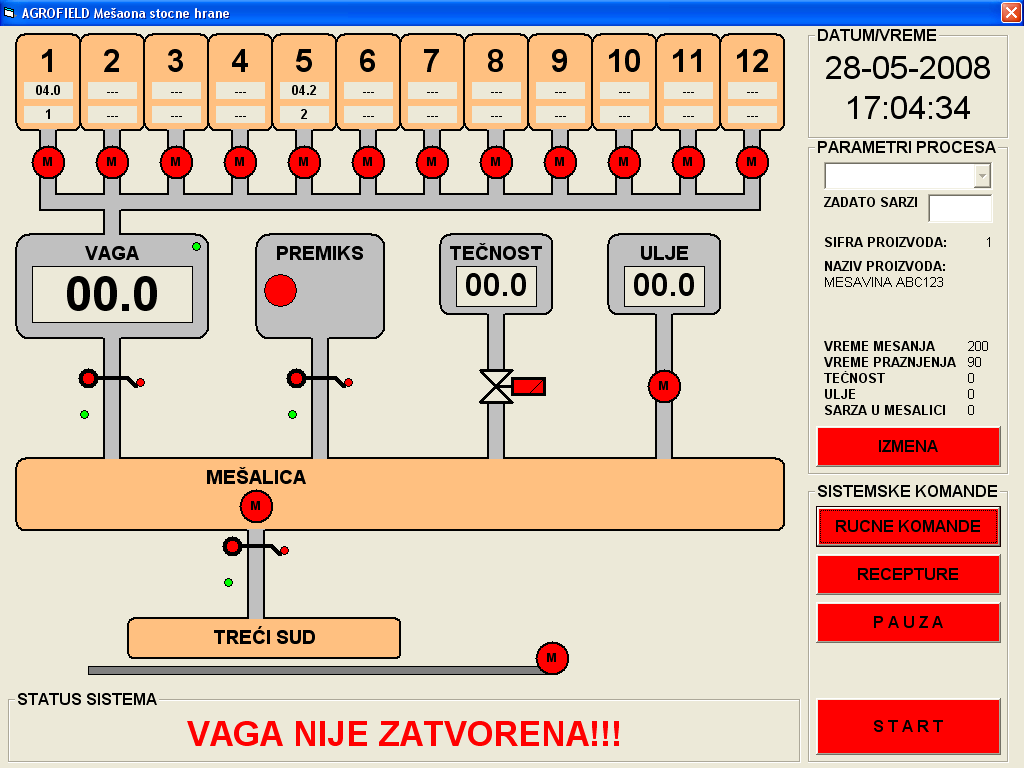

A module for managing the mixing of components

It combines the following functionalities

– Downloading recipes from the synthesis module

- Computer control of raw material weighing

– Computer monitoring, control and management of mixing parameters

– Computer monitoring of the mixing process in real time

– Optimization of the mixing process

Module for managing packaging of finished products

It combines the following functionalities

- Quantitative control for packaging of finished products

- Packaging record

- Material and financial records in the warehouse of finished products

- Statistics